-

DIY Polycarbonate Lean-To Roof Kit

Vendor:Roofing4US PolycarbonatefromRegular price $324.29Sale price $324.29 Regular priceUnit price per -

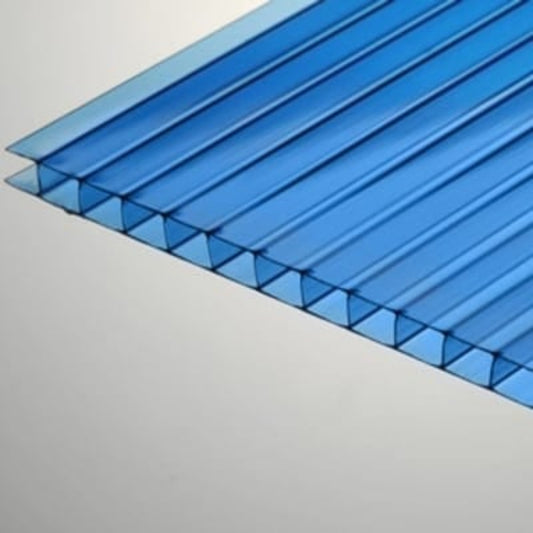

Twinwall Polycarbonate Sheet - All Sizes

Vendor:Roofing4US PolycarbonatefromRegular price $41.78Sale price $41.78 Regular priceUnit price per -

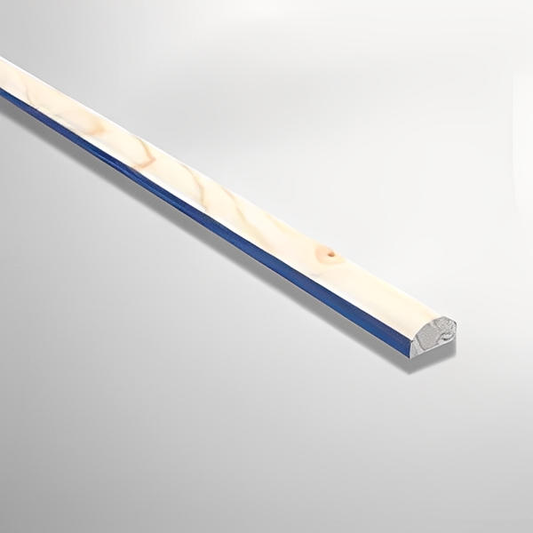

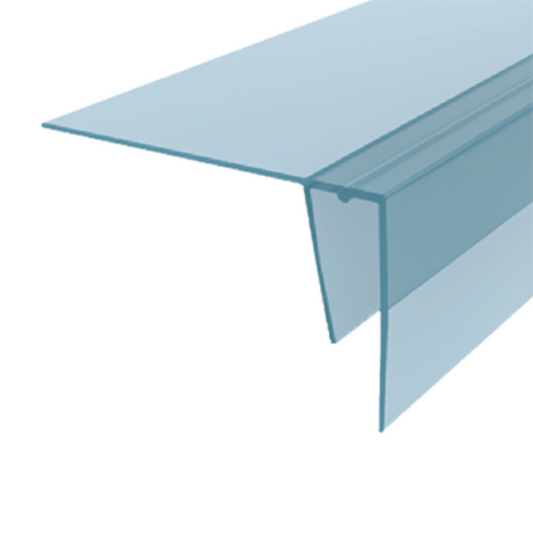

U-Channel - All Sizes

Vendor:Roofing4US PolycarbonatefromRegular price $7.27Sale price $7.27 Regular priceUnit price per -

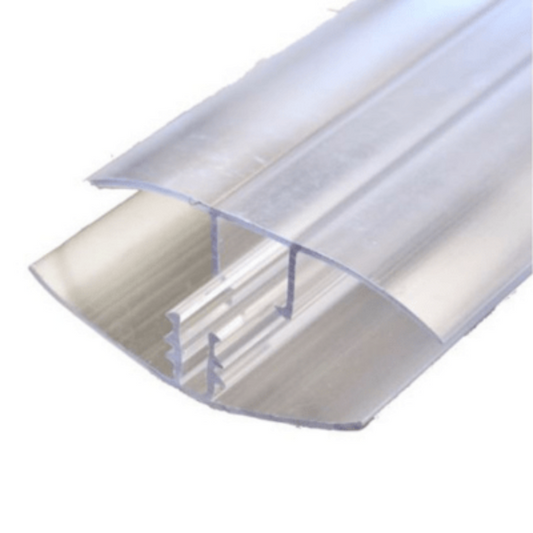

H-Channel For Twinwall Polycarbonate Sheet - All Sizes

Vendor:Roofing4US PolycarbonatefromRegular price $17.22Sale price $17.22 Regular priceUnit price per -

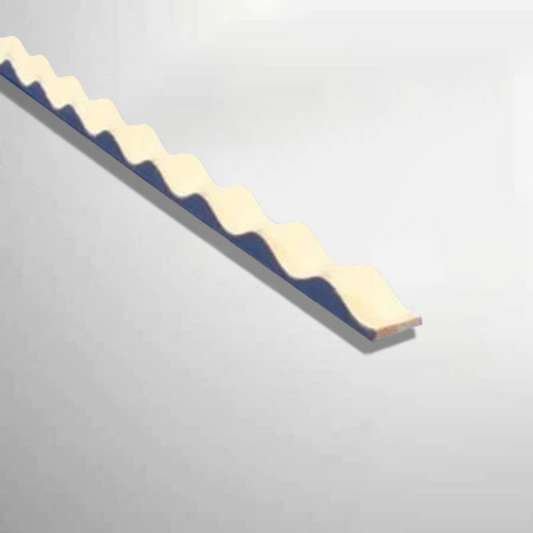

Multiwall Tape - 1 In x 150ft

Vendor:Roofing4US PolycarbonateRegular price $60.00Sale price $60.00 Regular priceUnit price per -

Multivent Tape - 1 In x 110ft

Vendor:Roofing4US PolycarbonateRegular price $61.64Sale price $61.64 Regular priceUnit price per -

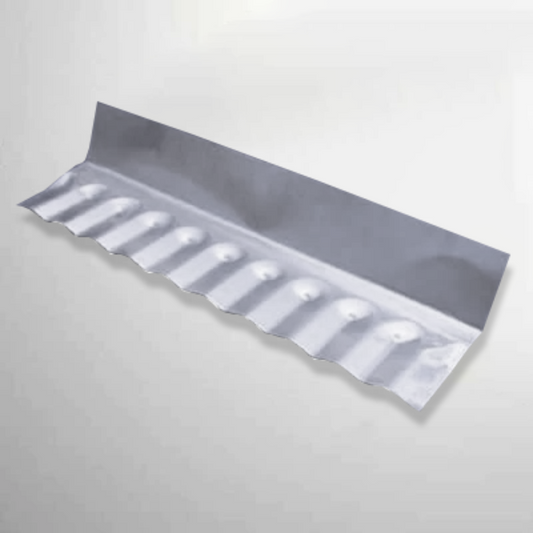

6 Oz Corrugated Fiberglass Sheet - All Sizes

Vendor:Roofing4US PolycarbonatefromRegular price $61.02Sale price $61.02 Regular priceUnit price per -

8 Oz Clear Corrugated Fiberglass Sheet - All Sizes

Vendor:Roofing4US PolycarbonatefromRegular price $95.93Sale price $95.93 Regular priceUnit price per -

R-Panel 8 Oz White Fiberglass Sheet - All Sizes

Vendor:Roofing4US PolycarbonatefromRegular price $144.61Sale price $144.61 Regular priceUnit price per -

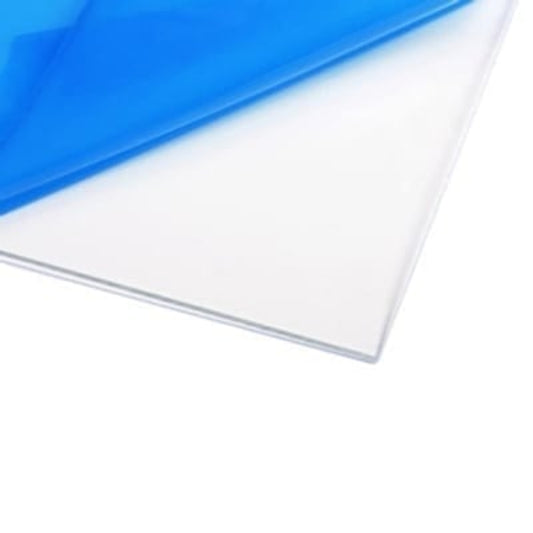

Clear Acrylic Sheet - All Sizes

Vendor:Roofing4US PolycarbonatefromRegular price $52.61Sale price $52.61 Regular priceUnit price per -

Replacement Dome For Tubular Skylight - All Sizes

Vendor:Sun-TekfromRegular price $112.10Sale price $112.10 Regular priceUnit price per$0.00 -

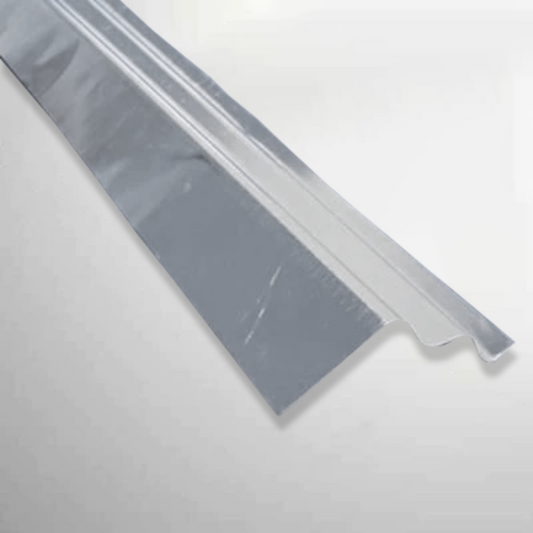

Snap H Profile - 6mm - 10mm - All Sizes

Vendor:Roofing4US PolycarbonatefromRegular price $41.70Sale price $41.70 Regular priceUnit price per

People also searched for...

polycarbonate hurricane panelsPolycarbonate Panels | Polycarbonate Sheet | Polycarbonate Sheets | Sheets

Welcome to the Polycarbonate Panels category at Roofing4us. This section is designed to provide a comprehensive look into the varied types of polycarbonate panels we offer, delve into their practical applications, and guide you in choosing the right panel for your specific needs.

About Polycarbonate Panels

Polycarbonate panels are known for their robust strength, lightweight properties, and excellent resistance to weather elements. Their ability to transmit light makes them an ideal choice for various applications, especially when you want to maximize natural light while benefiting from a strong protective layer.

Types of Polycarbonate Panels

1. DIY Polycarbonate Lean-To Roof Kit

A deal for homeowners looking for an easy-to-install roofing solution for their patios, carports, or outdoor storage spaces. This kit simplifies the installation process, especially for DIY enthusiasts.

2. Clear Hammered Sheet - All Sizes

Perfect for those aiming for a decorative touch, thanks to its unique hammered finish. Suitable for pergolas, patios, and interior partitions. Offers light diffusion with its distinctive texture while still being robust.

3. Greca Polycarbonate Corrugated Clear Roofing Sheet - All Colors

This is best used for greenhouses, sheds, and awnings. The corrugated design adds structural strength. Available in various colors, it allows users to match their aesthetic preferences.

4. Multiwall Polycarbonate Sheet - All Sizes

These are highly recommended for greenhouses, sunrooms, and other outdoor structures that demand enhanced insulation. Multiple layers provide better insulation while ensuring light transmission.

5. Twinwall Polycarbonate Sheet - All Sizes

A midpoint between single sheets and multiwall sheets, it’s great for patios, greenhouses, and canopies. Offers an optimal balance of insulation and weight.

Selecting the Right Panel

- Consider Your Use Case: Different applications demand different types of panels. For instance, for insulation-focused projects, multiwall or twinwall sheets might be ideal.

- Look at Aesthetics: Decide on the look you desire. For a more decorative finish, the Clear Hammered Sheet is an excellent choice.

- Factor in Budget: With a range of options available, you can pick a product that fits your budget without compromising on quality.

Polycarbonate Panels

Polycarbonate panels are sheets made from a durable and lightweight thermoplastic material known as polycarbonate. These panels are transparent or translucent and have diverse uses due to their unique properties. Common applications include roofing for buildings, skylights to allow natural light, greenhouse glazing, safety glazing for protective barriers, room dividers, noise barriers, signage, swimming pool enclosures, and decorative elements in interior design. Polycarbonate panels are valued for their impact resistance, light transmission, and thermal properties, making them versatile and valuable in various industries and architectural projects.

Pros of polycarbonate sheets

Polycarbonate sheets offer several advantages, including remarkable impact resistance, making them virtually unbreakable and highly protective in various applications. Being lightweight, they simplify handling and installation compared to glass. These sheets provide excellent optical clarity, allowing for high light transmission without distortion, making them well-suited for applications requiring transparency.

Additionally, sheets of polycarbonateoften come with built-in UV protection, preventing yellowing or deterioration when exposed to prolonged sunlight. They also provide effective thermal insulation, contributing to temperature regulation and potential energy savings in certain applications.

Their flexibility and ease of fabrication enable diverse uses, and their resistance to weathering ensures long-lasting performance even in harsh environmental conditions. Moreover, polycarbonate sheets exhibit good fire resistance properties, enhancing safety in specific applications.

Their versatility makes them suitable for various purposes, such as roofing, glazing, safety barriers, skylights, and signage, among others. Their extended lifespan further adds to their appeal, reducing the need for frequent replacements and overall maintenance costs.

While sheets of polycarbonate may have a higher initial cost compared to some alternatives, their long-term benefits and durability make them a cost-effective choice for projects requiring lasting performance and reliable transparency.

Polycarbonate sheet vs Acrylic sheet

Sheets of polycarbonate and acrylic sheets are two different types of transparent materials, each with its unique characteristics and applications. Let's compare polycarbonate sheets and acrylic sheets based on various factors:

1. Material Composition:

- Polycarbonate Sheets: Polycarbonate is a durable thermoplastic material known for its exceptional impact resistance and flexibility.

- Acrylic Sheets: Acrylic, also known as PMMA (poly(methyl methacrylate)), is a transparent thermoplastic with excellent optical clarity and rigidity.

2. Impact Resistance:

- Polycarbonate Sheets: Sheets of polycarbonate are highly impact-resistant and virtually unbreakable, making them ideal for applications requiring robust protection against impacts or vandalism.

- Acrylic Sheets: Acrylic sheets are more brittle compared to polycarbonate, making them less impact-resistant and more prone to cracking or shattering upon impact.

3. Optical Clarity:

- Sheets of Polycarbonate: Polycarbonate offers good optical clarity, but it may have slight variations in transparency due to its molecular structure.

- Acrylic Sheets: Acrylic provides excellent optical clarity similar to glass, making it an ideal choice for applications requiring high transparency.

4. UV Resistance:

- Sheets of Polycarbonate: Sheets Polycarbonate often come with built-in UV protection, making them resistant to yellowing or degradation when exposed to sunlight for extended periods.

- Acrylic Sheets: Acrylic sheets are more susceptible to yellowing and degradation when exposed to UV radiation over time.

5. Flexibility:

- Sheets of Polycarbonate : Polycarbonate is more flexible than acrylic, allowing it to withstand deformation without breaking, contributing to its impact resistance.

- Acrylic Sheets: Acrylic is rigid and less flexible compared to polycarbonate, making it more prone to cracking under pressure.

6. Weight:

- Polycarbonate Sheets: Sheets of Polycarbonate are lightweight, making them easier to handle and install compared to glass.

- Acrylic Sheets: Acrylic sheets are lighter than glass but slightly heavier than polycarbonate.

What is a clear polycarbonate sheet?

A clear sheet of polycarbonate is a transparent or translucent panel crafted from polycarbonate, a durable and lightweight thermoplastic material. This type of sheet is renowned for its outstanding clarity, enabling light to pass through with minimal distortion, similar to glass. Clear polycarbonate sheets are available in various thicknesses and sizes, catering to diverse application needs.

These sheets possess numerous advantages, including high impact resistance, rendering them nearly unbreakable and well-suited for scenarios requiring protection from impacts. Additionally, they offer excellent optical clarity, making them ideal for situations that demand transparency or visibility.

Clear sheets of polycarbonate find common use across a wide range of applications, such as greenhouse glazing, skylights, safety glazing, protective barriers, transparent partitions, display panels, signage, noise barriers, and more. Their versatility, durability, and optical properties make them valuable in various industries, encompassing construction, architecture, agriculture, transportation, and manufacturing.

Due to their lightweight nature, impact resistance, and ability to maintain optical clarity over time, clear sheets of polycarbonate serve as an attractive alternative to glass in numerous applications. They offer a robust and see-through solution for projects requiring both visibility and protection, thereby presenting numerous practical and innovative possibilities for architects, designers, and engineers.

Is polycarbonate clear compared to acrylic sheet?

Yes, sheets of polycarbonate are generally more transparent than acrylic sheets. While both materials are transparent and provide excellent optical clarity, polycarbonate has the advantage of offering superior transparency, especially in thicker sheets.

Acrylic sheets have excellent optical clarity, similar to glass, making them a great choice for applications that require high transparency. However, in thicker panels, acrylic may exhibit slight variations in transparency, which can impact the overall clarity.

On the other hand, sheets of polycarbonate maintain consistently high optical clarity, even in thicker panels. Their molecular structure ensures they maintain excellent transparency without significant variations, providing a clearer view of the material.

So, if maximum clarity is essential for a specific application, sheets of polycarbonate are generally preferred over acrylic sheets due to their superior transparency. However, the final decision between the two materials will depend on the specific requirements of the project, considering factors such as impact resistance, UV protection, flexibility, and cost.

How long does polycarbonate last?

The lifespan of polycarbonate can vary depending on several factors, including its thickness, quality, specific usage, and environmental conditions. On average, sheets of polycarbonate can endure for approximately 10 to 20 years or even longer, provided they receive proper care and maintenance.

The durability and longevity of high-quality sheets of polycarbonate can be further enhanced if they are adequately protected against UV radiation, which helps prevent yellowing or degradation caused by prolonged sunlight exposure. Additionally, thicker sheets generally offer better impact resistance and may have a longer lifespan in certain applications.

To maximize the lifespan of polycarbonate, it is crucial to ensure proper installation and regular maintenance. Periodic cleaning using gentle methods, avoiding harsh chemicals, and protecting the material from scratches or excessive force can contribute to its lasting performance.

For outdoor applications like roofing, skylights, or protective barriers, choosing polycarbonate sheets with UV protection is essential to withstand environmental elements and maintain their strength and clarity over time.

While polycarbonate is known for its durability and impact resistance, accurately estimating its lifespan requires considering its specific use and the prevailing environmental factors. Conducting regular inspections and replacing sheets when needed can help sustain the enduring performance and longevity of polycarbonate materials.

Benefits of Polycarbonate Panels

- Superior Impact Resistance – Up to 200 times stronger than glass, making it ideal for high-impact areas or storm-prone regions.

- UV Protection – Filters out harmful UV rays while allowing in natural light, protecting interiors and plants.

- Lightweight & Easy to Handle – Simplifies installation, reduces labour costs, and works well for DIY projects.

- Excellent Thermal Insulation – Multiwall panels offer high insulation values, helping reduce heating and cooling costs.

- Weather-Resistant – Withstands rain, hail, and sun exposure without yellowing, cracking, or fading.

- Flexible Use – Can be cut to size and curved, making them suitable for a variety of custom designs.

Applications of Polycarbonate Panels

- Greenhouses – Encourage plant growth with light-permeable panels.

- Pergolas & Awnings – Create shaded outdoor areas without sacrificing brightness.

- Carports & Garages – Protect vehicles while maintaining airflow and visibility.

- Skylights & Sunrooms – Let natural light in without the weight or fragility of glass.

- DIY Projects & Sheds – Great for garden buildings, lean-tos, and other personal constructions.

- Commercial Roofing & Facades – Durable and sleek solutions for retail, office, or industrial buildings.

Why Choose Roofing4US?

- Trusted Supplier of Premium Products – We offer only high-quality polycarbonate panels from reputable manufacturers.

- Wide Range of Options – From clear to bronze, solid to multiwall, we stock various thicknesses and finishes to suit any requirement.

- Competitive Pricing – Get high performance at great value without compromising on quality.

- Expert Advice & Support – Need help choosing the right panel? Our friendly team is here to guide you every step of the way.

- Fast Delivery Across the US – Get your project started quickly with prompt shipping on all orders.

Rated Excellent

Rated Excellent