-

Twinwall Polycarbonate Sheet - All Sizes

Vendor:Roofing4US PolycarbonatefromRegular price $41.78Sale price $41.78 Regular priceUnit price per

Polycarbonate Siding

Welcome to the Polycarbonate Siding section on Roofing4us.com! Polycarbonate siding is revered for its combination of strength, durability, and versatility. Suitable for a myriad of applications, from greenhouse panels to outdoor roofing, polycarbonate offers the best of both worlds when it comes to function and aesthetics.

Let's delve into the various types of polycarbonate siding products available and explore how they can meet your needs.

Clear Hammered Sheet

The Clear Hammered Sheet brings with it a unique textured finish that not only provides a distinctive aesthetic but also aids in diffusing light. This makes it especially beneficial for settings where you want both light penetration and a level of privacy. The hammered pattern further offers added strength to the sheet.

Greca Polycarbonate Corrugated Clear Roofing Sheet

Corrugated sheets are renowned for their wave-like design, offering added structural strength. The Greca variant integrates this corrugated design with the clarity of polycarbonate, making it ideal for roofing applications where light transmission is desired. Available in multiple colors, this sheet is versatile for various design needs.

Multiwall Polycarbonate Sheet

Multiwall sheets consist of multiple layers, providing an unparalleled combination of thermal insulation, light diffusion, and strength. These are perfect for spaces where energy efficiency is paramount, such as sunrooms or patios.

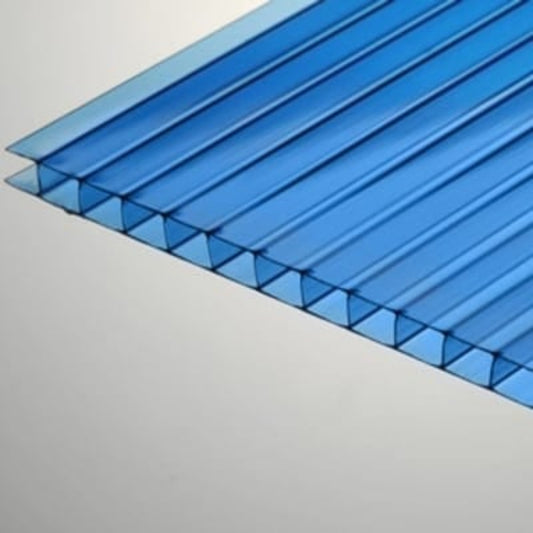

Twinwall Polycarbonate Sheet

Twinwall sheets are a subcategory of multiwall sheets with two distinct layers. They offer a balance between the insulation of multiwall sheets and the simplicity of single sheets. Suitable for a variety of applications, twinwall sheets are available at a special sale price.

Polycarbonate Siding

Polycarbonate siding is a type of exterior cladding used to protect and cover building walls. It is made from durable and impact-resistant polycarbonate, a thermoplastic material known for its UV stability. Polycarbonate siding is lightweight, transparent, and requires minimal maintenance, making it a popular choice for various buildings. Its installation can be done in different orientations, providing an attractive and practical option for enhancing the appearance of modern and contemporary architectural designs.

Features of polycarbonate siding

Durability: Polycarbonate siding is highly resistant to impact, making it a long-lasting option that can withstand harsh weather conditions, including hail and heavy winds.

UV Resistance: The material is UV stable, which means it won't discolor or degrade when exposed to sunlight for extended periods. This ensures the siding's color and appearance remain intact over time.

Lightweight: Compared to traditional siding materials like wood, brick, or metal, polycarbonate siding is lightweight, making installation easier and reducing the overall load on the building structure.

Transparency: Polycarbonate siding is available in various levels of transparency, allowing natural light to pass through, creating a bright and inviting interior space.

Insulation: Some polycarbonate siding products are designed with built-in insulation properties, enhancing energy efficiency and reducing heating and cooling costs.

Low Maintenance: Due to its resilience, polycarbonate siding requires minimal maintenance. Regular cleaning with mild soap and water is usually sufficient to keep it looking good.

Are polycarbonate plastic sidings and polycarbonate panels similar?

Polycarbonate sidings and polycarbonate panels share the same material, polycarbonate, but they serve distinct purposes and find application in different areas.

Polycarbonate Sidings:

Polycarbonate sidings are utilized as protective cladding on building exteriors. Their primary function is to shield walls from weather elements such as rain, wind, and UV rays. These sidings come in various styles and are commonly employed in residential, commercial, and industrial structures, offering both durability and an enhanced visual appeal.

Polycarbonate Panels:

In contrast, polycarbonate panels refer to flat sheets or panels made from polycarbonate material. These versatile panels serve various purposes and can be either transparent or translucent, ensuring the passage of light while maintaining impressive impact resistance. Common applications of polycarbonate panels include greenhouses, skylights, roofing, partitions, and a multitude of architectural and do-it-yourself projects where lightweight, durability, and transparency are crucial.

To summarize, while both polycarbonate sidings and polycarbonate panels share the advantages of being durable and impact-resistant, they are distinct in function. Polycarbonate sidings are designed specifically for exterior wall cladding to protect buildings, while polycarbonate panels find use in diverse areas, ranging from roofing to transparent applications like skylights.

How long does polycarbonate plastic roof sheets last?

The lifespan of polycarbonate plastic roof sheets can vary based on factors such as material quality, product type, and environmental conditions during installation. When installed and maintained correctly, good-quality polycarbonate roof sheets can endure for around 15 to 30 years or even longer, with some premium options having extended longevity. Factors affecting their lifespan include material quality, UV protection, proper installation, regular maintenance, local climate, and exposure to extreme weather conditions. To ensure optimal performance and durability, it's essential to buy from reputable suppliers, adhere to manufacturer guidelines, and conduct routine inspections and cleaning. Consulting the manufacturer's specifications will give a more precise estimate of the roof sheets' expected lifespan.

Which is more durable polycarbonate panels or acrylic panels?

When comparing polycarbonate panels and acrylic panels, polycarbonate emerges as the more durable option. Polycarbonate is renowned for its outstanding toughness and resistance to impact, making it practically unbreakable even under significant stress. In contrast, acrylic panels, while possessing strength and good optical clarity, tend to be more brittle and susceptible to cracking or breaking when subjected to substantial impact.

In scenarios where durability and impact resistance are paramount, such as in construction, safety barriers, or automotive components, polycarbonate panels are the preferred choice. They excel at enduring harsh conditions, ensuring long-lasting performance. Acrylic panels, on the other hand, are commonly utilized in applications that prioritize optical clarity, including display cases, signage, lighting fixtures, and artistic installations.

To sum up, if you require a material capable of withstanding rigorous use and resisting impact, polycarbonate panels offer superior performance. However, for applications focusing on optical quality, acrylic panels may prove to be the more suitable option. Ultimately, the decision between the two depends on the specific requirements of your project or application.

Rated Excellent

Rated Excellent