-

Twinwall Polycarbonate Sheet - All Sizes

Vendor:Roofing4US PolycarbonatefromRegular price $41.78Sale price $41.78 Regular priceUnit price per

People also searched for...

clear roof panels for pergola<p><span style="background-color:rgb(255,255,255);color:rgb(0,0,0);">Pergola Roof Panels | Sheets | Pergola | Roofing</span></p>

Discover the exquisite variety of pergola roof panels available exclusively at Roofing4Us.com. As your reliable partner in outdoor aesthetics, we're proud to present a curated collection of roof panels, offering both form and function. Dive into the world of pergola roof panels with us and make an informed choice.

Material & Design Groups

Clear Hammered Sheet

A classic favorite, the Clear Hammered Sheet is perfect for those seeking an elegant, traditional touch. Its unique hammered design not only looks stunning but also provides an added layer of texture. Perfect for any pergola type, it ensures a clear view of the sky while protecting against the elements.

Greca Polycarbonate Corrugated Sheet

These sheets bring a Mediterranean touch to your pergola. Greca Polycarbonate Corrugated Clear Roofing Sheets come in all colors, allowing users to choose according to their design preference. These sheets offer excellent protection from rain, while the corrugated design ensures strength and durability.

Multiwall Polycarbonate Sheet

Sophistication meets performance. Multiwall Polycarbonate Sheets are renowned for their enhanced insulation properties and resistance against harsh weather. They create a seamless look and are ideal for pergolas that aim to be more energy-efficient.

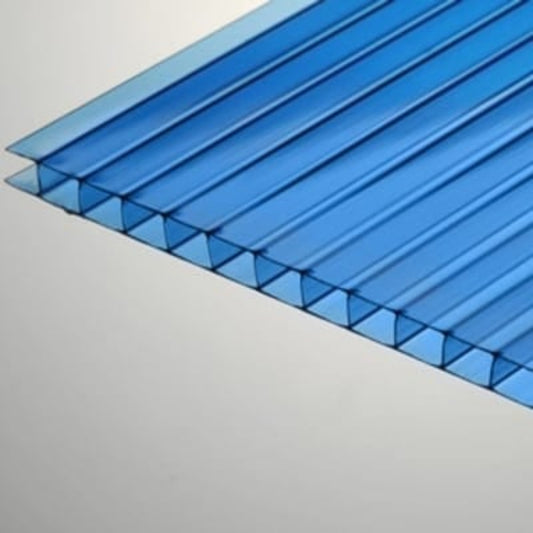

Twinwall Polycarbonate Sheet

Blending the benefits of durability and insulation, Twinwall Polycarbonate Sheets offer a dual-layered approach to pergola roofing. These sheets serve both functional and aesthetic purposes, making them a popular choice for many homeowners.

Pergola Roof Panels

Pergola roof panels are panels specifically designed to cover the top of a pergola, providing protection from various weather elements and creating a shaded area underneath. These panels come in diverse materials and styles, allowing homeowners to customize both the appearance and functionality of their pergola.

There are several types of panels for pergola roof available, including:

Polycarbonate Panels: These panels are either clear or translucent, effectively shielding against rain and harmful UV rays while still permitting diffused light to enter. Their high durability and near-unbreakable properties make them an excellent choice for long-term outdoor use.

Fabric Canopy: Fabric canopies are lightweight and versatile, delivering shade while promoting air circulation. With a range of colors and designs available, they also introduce a stylish element to the overall pergola aesthetic.

Retractable Roof Systems: Such systems consist of panels that can be easily opened or closed, providing homeowners with the flexibility to control the amount of shade or sunlight they desire.

Wood Panels: Wooden roof panels offer a more natural and rustic appearance, imparting a charming touch to the pergola. While they provide partial shade and protection against light rain, they may require more regular maintenance.

Metal Panels: Metal roof panels, such as those made from aluminum or steel, are highly durable and can withstand harsh weather conditions. Available in various finishes, they can lend a modern and sleek look to the pergola design.

Selecting the appropriate pergola roof panels depends on factors like budget, desired level of shade, weather resistance, and individual preferences. Each type of panel offers unique advantages, enabling homeowners to create a comfortable and visually appealing outdoor space beneath their pergola.

Which are the most durable roof panels for pergola roof?

The most durable roof panels for a pergola roof are typically made from polycarbonate and metal materials.

Polycarbonate Panels: Polycarbonate roof panels are highly durable and known for their exceptional impact resistance. They are virtually unbreakable, making them an excellent choice for withstanding harsh weather conditions and potential impacts from hail or debris. Polycarbonate panels also offer protection against harmful UV rays, ensuring longevity and minimal discoloration over time. These panels are a popular option for pergola roofs due to their combination of durability and optical clarity.

Metal Panels: Metal roof panels, such as those made from aluminum or steel, are also highly durable and can withstand various weather conditions. They are resistant to corrosion, moisture, and fading, making them suitable for long-term outdoor use. Metal panels are robust and capable of handling heavy loads, making them an ideal choice for areas with extreme weather or snow accumulation. Additionally, metal panels offer a sleek and modern appearance, complementing various architectural styles.

When it comes to durability, polycarbonate and metal roof panels stand out as the top choices for a pergola roof. Both materials provide excellent resistance to the elements and ensure the pergola remains a sturdy and long-lasting outdoor structure.

How long does polycarbonate roof panels last?

The longevity of polycarbonate roof panels can vary based on several factors, including the quality of the material, the level of UV protection, prevailing climate conditions, and maintenance practices.

On average, high-quality polycarbonate roof panels with UV protection can last anywhere from 15 to 30 years or even more. Polycarbonate is well-regarded for its outstanding durability and resistance to impacts, contributing to its extended lifespan. It is essential to select polycarbonate panels with adequate UV protection, as prolonged exposure to UV rays can cause degradation and reduce the panels' overall lifespan.

Proper maintenance also plays a pivotal role in prolonging the life of polycarbonate roof panels. Regular cleaning to remove dirt, debris, and potential mold growth is advisable. It is important to avoid using abrasive cleaning materials that might scratch the panel surface, as this could compromise their durability and optical clarity over time.

Furthermore, the geographical location and prevailing weather conditions can significantly influence the longevity of polycarbonate roof panels. Regions experiencing extreme temperatures, frequent hailstorms, or heavy snow loads may subject the panels to greater stress, potentially affecting their lifespan.

Overall, when correctly installed and well-maintained, polycarbonate roof panels prove to be a durable and long-lasting roofing solution for various applications, including pergolas, greenhouses, and outdoor shelters.

Are acrylic roof panels worth it?

The worthiness of acrylic roof panels depends on the specific requirements and objectives of the project. Acrylic roof panels offer several advantages that make them a compelling option for certain applications:

Clarity: Acrylic roof panels provide exceptional optical clarity, allowing abundant natural light to pass through while still providing some degree of shade. This quality is ideal for spaces where a well-lit and visually appealing environment is desired.

Lightweight: Compared to glass and certain other roofing materials, acrylic roof panels are lighter, making them easier to handle and install. This can lead to cost savings in terms of transportation and installation.

Impact Resistance: While not as robust as polycarbonate, acrylic roof panels still offer decent impact resistance and can withstand moderate impacts, such as hail or small debris.

UV Resistance: High-quality acrylic roof panels typically come with UV protection, preventing yellowing and degradation due to prolonged exposure to sunlight.

Aesthetics: Acrylic roof panels have a sleek and modern appearance, adding an elegant touch to architectural designs.

However, there are some considerations when using acrylic roof panels:

Durability: Acrylic is not as impact-resistant as polycarbonate, making it less suitable for areas prone to severe weather conditions or places with a high risk of impact.

Susceptibility to Scratches: Acrylic can be more prone to scratching, necessitating careful handling during installation and maintenance to avoid damaging the panels.

Cost: Acrylic roof panels can be more expensive than certain other roofing materials, such as polycarbonate or metal.

In summary, acrylic roof panels can be a valuable choice for specific applications that prioritize optical clarity, lightweight construction, and aesthetic appeal. However, for projects requiring higher impact resistance and durability, polycarbonate or metal roof panels may be more appropriate. It is crucial to evaluate the unique needs of the project and carefully consider the benefits and limitations of acrylic roof panels before making a decision.

What is difference between metal sheets & plastic sheets?

The primary distinctions between metal sheets and plastic sheets lie in their composition, physical characteristics, and applications:

Composition:

Metal sheets are crafted from a variety of metals such as steel, aluminum, copper, and zinc, offering strength, durability, and resistance to fire and extreme weather conditions.

Plastic sheets, however, are made from different types of polymers like polyethylene, polyvinyl chloride (PVC), polycarbonate, and acrylic. Plastic sheets are generally lighter in weight compared to their metal counterparts.

Physical Properties:

Metal sheets are rigid and possess high tensile strength, making them suitable for load-bearing purposes in roofing, construction, and industrial settings.

Plastic sheets, depending on the specific polymer used, can exhibit varying levels of flexibility. While some plastics are rigid and durable, others are more pliable and can be molded into different shapes.

Applications:

Metal sheets find common use in roofing, siding, building facades, industrial structures, and automotive applications due to their strength and durability.

On the other hand, plastic sheets are employed in areas such as packaging, signage, greenhouse glazing, protective barriers, and specific roofing applications where weight and cost considerations are important.

Thermal Conductivity:

Metal sheets have higher thermal conductivity, allowing for quick heat transfer, which might necessitate additional insulation in certain applications.

Conversely, plastic sheets generally have lower thermal conductivity, making them suitable for situations where insulation is required or when minimizing heat transfer is essential.

Corrosion Resistance:

Metal sheets made from specific metals, like stainless steel or aluminum, provide excellent corrosion resistance, making them suitable for outdoor applications where exposure to moisture is a concern.

Plastic sheets, particularly those composed of corrosion-resistant polymers, are often preferred in marine, chemical, or corrosive environments where metal sheets may not be as appropriate.

In conclusion, metal sheets are renowned for their strength, durability, and thermal conductivity, while plastic sheets offer various degrees of flexibility and corrosion resistance. The choice between the two depends on the specific requirements of the application, budget considerations, and the desired properties of the material.

Rated Excellent

Rated Excellent