-

DIY Polycarbonate Lean-To Roof Kit

Vendor:Roofing4US PolycarbonatefromRegular price $291.86Sale price $291.86 Regular priceUnit price per$0.00 -

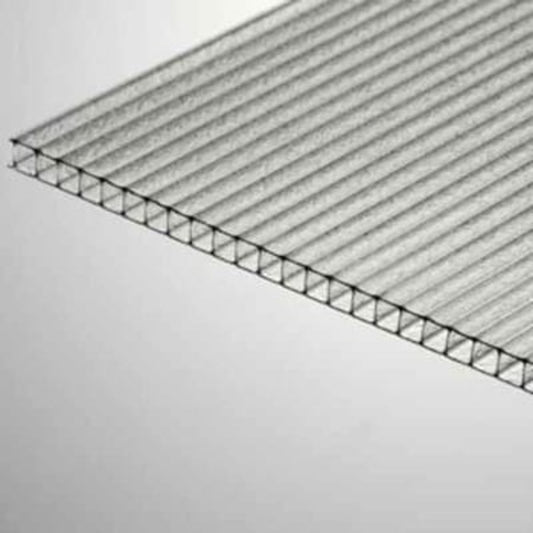

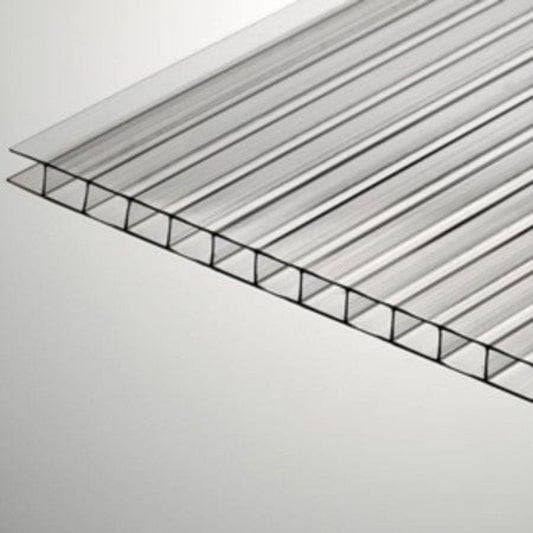

Twinwall Polycarbonate Sheet - All Sizes

Vendor:Roofing4US PolycarbonatefromRegular price $37.60Sale price $37.60 Regular priceUnit price per$0.00

Clear Polycarbonate Sheets | Polycarbonate Sheet | Roofing Sheets

Discover our exceptional collection of clear polycarbonate sheets at Roofing4us.com. Engineered for strength and durability, these sheets offer a practical, lightweight solution for various roofing needs. The sheets are transparent, allowing excellent natural light transmission, making them ideal choices for greenhouses, sunrooms, and other outdoor structures. Our sheets are available in various sizes and designs, ensuring the right fit for any project. With Roofing4us.com, quality, versatility, and the assurance of a long-lasting roof are always guaranteed.

What Are Clear Polycarbonate Sheets?

Clear polycarbonate sheets are lightweight, high-impact roofing and glazing materials known for their exceptional clarity and strength. Made from thermoplastic polymers, they offer superior light transmission while remaining virtually unbreakable. These sheets are commonly used as a safer, more durable alternative to glass in residential, commercial, and agricultural applications.

Types of Clear Polycarbonate Sheets:

DIY Polycarbonate Kits:

DIY Polycarbonate Lean-To Roof Kit: Perfect for those who enjoy hands-on projects, these kits come with everything required to create a lean-to roof. Great for carports or covered patios.

Texture-Based Sheet:

Clear Hammered Sheet - All Sizes: These sheets offer a unique textured design that provides a blend of clarity and privacy. Ideal for decorative outdoor structures.

Design-Based Sheets:

Greca Polycarbonate Corrugated Clear Roofing Sheet - All Colors: With a classic corrugated design, these sheets provide an aesthetic appeal alongside functionality. Suitable for both residential and commercial structures.

Multi-Layered Sheets:

Twinwall Polycarbonate Sheet - All Sizes: These double-walled sheets offer enhanced insulation and durability. Ideal for greenhouses and sunrooms, they protect against UV rays while ensuring temperature control.

Guidance on Selection of Polycarbonate Plastic Sheet

- For DIY enthusiasts or those looking to construct a lean-to structure, the DIY Polycarbonate Lean-To Roof Kit is a straightforward option.

- If aesthetics matter and you want a combination of privacy with light transmission, opt for the Clear Hammered Sheet.

- For traditional roofing aesthetics combined with the benefits of polycarbonate, the Greca Polycarbonate Corrugated Sheet is a top choice.

- If insulation and protection against elements are a priority, especially in structures like greenhouses, the Twinwall Polycarbonate Sheet provides an optimal solution.

Clear Polycarbonate Sheets

Clear polycarbonate sheets are transparent panels made from a durable and versatile thermoplastic material called polycarbonate. These sheets are well-known for their exceptional clarity, allowing light to pass through while maintaining visibility. They offer a variety of benefits and have numerous applications in different industries and settings.

Key features and uses of clear polycarbonate sheets include:

- Transparency: Clear polycarbonate sheets have high light transmission, making them suitable for situations where visibility and natural light are important.

- Impact Resistance: These sheets are highly durable and can withstand strong impacts without shattering, making them an excellent choice for safety and security purposes.

- Lightweight: Compared to glass, clear polycarbonate sheets are lighter, making handling and installation easier.

- UV Protection: Many clear polycarbonate sheets come with built-in UV protection, blocking harmful UV rays while still allowing beneficial light to pass through.

- Weather Resistance: Clear polycarbonate sheets are designed to withstand harsh weather conditions, making them suitable for outdoor use.

- Customizability: They can be easily cut, shaped, and molded into various sizes and forms, providing flexibility in design and application.

Benefits of Clear Polycarbonate Sheet

- High Light Transmission: Allows up to 90% natural light to pass through, reducing the need for artificial lighting.

- Impact & Weather Resistance: Withstands hail, high winds, heavy rain, and UV exposure without cracking or yellowing.

- Lightweight & Easy to Handle: Half the weight of glass—easy to lift, cut, and install.

- UV Protection: Built-in UV coating prevents discoloration and protects interiors from harmful sun exposure.

- Energy Efficient: Helps regulate indoor temperatures and supports energy-saving designs.

- Versatile Finishes: Available in corrugated, smooth, hammered, and twin-wall options to suit any aesthetic or function.

Applications of Clear Polycarbonate Panels

- Greenhouses & Cold Frames: Ideal for horticultural use due to maximum light diffusion and thermal insulation (especially twin-wall).

- Carports & Patio Covers: Provides a protective yet light-permeable canopy.

- Skylights & Rooflights: Offers natural lighting without compromising strength or safety.

- DIY Sheds & Lean-Tos: Lightweight, cut-to-size sheets are perfect for home improvement projects.

- Industrial Roofs & Canopies: Used in commercial settings for durable, long-lasting daylighting solutions.

- Sound Barriers & Safety Glazing: Excellent for areas requiring strength, clarity, and noise reduction.

Installation Tips for Clear Polycarbonate Sheets

- Pre-drill fixing holes slightly larger than the screw diameter to allow for thermal expansion.

- Install with the UV-protected side facing out (check sheet labelling).

- Use compatible accessories, such as closure strips, flashing, and joining profiles, to ensure water-tightness and stability.

- Leave expansion gaps between sheets and structural elements.

- Use a fine-toothed blade or circular saw for accurate cutting without cracking the panel.

- Avoid over-tightening screws, which can warp the sheet or cause stress points.

What are the similarities between polycarbonate & acrylic sheets?

Polycarbonate and acrylic sheets share various similarities, making them popular choices for a wide range of applications. Here are the main points of resemblance between the two materials:

- Transparency: Both polycarbonate and acrylic sheets are transparent, offering high light transmission and excellent clarity. They provide visibility similar to glass and are commonly used in situations where see-through properties are essential.

- UV Resistance: Both polycarbonate and acrylic offer good UV resistance, safeguarding against harmful ultraviolet rays. This characteristic makes them suitable for outdoor applications, as they can maintain transparency and structural integrity over time, even when exposed to sunlight.

- Lightweight: Polycarbonate and acrylic are lighter than glass, making them easier to handle, transport, and install. Their lightweight nature contributes to cost savings during shipping and installation processes.

- Customizability: Both polycarbonate and acrylic can be easily cut, shaped, and molded into various sizes and forms. This versatility allows for customization to suit specific design requirements and applications.

- Thermoplastic Nature: Both polycarbonate and acrylic are thermoplastics, meaning they can be heated and reformed multiple times without significant degradation of their properties. This characteristic enables recycling and easy reshaping during manufacturing processes.

- Impact Resistance: While polycarbonate exhibits notably higher impact resistance than acrylic, both materials offer better impact resistance compared to traditional glass. They can withstand a certain level of force without shattering, making them safer alternatives for specific applications.

- Weather Resistance: Sheets of both polycarbonate and acrylic are designed to endure various weather conditions, including rain, snow, and temperature fluctuations. This feature makes them suitable for outdoor use in windows, skylights, and protective enclosures.

- Wide Range of Applications: Polycarbonate and acrylic sheets find utility across multiple industries, such as construction, architecture, automotive, aerospace, retail, and more. They are utilized for windows, glazing, signs, displays, protective barriers, and various other purposes.

While polycarbonate and acrylic sheets share these similarities, they also have distinct differences concerning impact resistance, cost, and thermal insulation properties. Understanding these similarities and differences can aid in selecting the most suitable material for specific project requirements.

Is polycarbonate sheet transparent and more clear compared to glass?

Polycarbonate type sheets are transparent and can exhibit greater clarity compared to glass. As a thermoplastic material, polycarbonate is known for its exceptional clarity, allowing light to pass through with minimal distortion. Due to its consistent manufacturing process, polycarbonate type sheets are often referred to as "transparent plastic," boasting high light transmission properties.

When compared to conventional glass, polycarbonate type sheets can offer superior clarity in specific applications. While glass is also transparent, it may have slight imperfections or variations in clarity during its manufacturing. In contrast, polycarbonate type sheets are engineered to maintain consistent clarity, making them an excellent choice for applications that require impeccable optical quality.

Additionally, the impact resistance of polycarbonate is another advantage over glass. Its durability makes polycarbonate type sheets a safer alternative in environments where breakage or shattering is a concern.

In conclusion, polycarbonate sheets are transparent and possess remarkable clarity, often outperforming traditional glass in certain applications. Their optical properties and impact resistance make them a sought-after option for a wide range of uses, including windows, skylights, protective barriers, and more.

Which is better plastic or polycarbonate?

The comparison between plastic and polycarbonate relies on the particular context and use. It's crucial to understand that polycarbonate belongs to the category of plastics. Therefore, the question can be restated as “Which is superior: polycarbonate or other plastic types?”

Let's analyze the contrast between polycarbonate and some common plastic types:

Polycarbonate vs. Acrylic:

Polycarbonate: Renowned for its outstanding impact resistance, polycarbonate is well-suited for applications that demand high durability and safety. It offers good UV resistance, a lightweight nature, and excellent transparency.

Acrylic: Also known as Plexiglas, acrylic provides excellent clarity and transparency akin to glass. It is lighter and more cost-effective than polycarbonate but lacks the same level of impact resistance.

Polycarbonate vs. PVC (Polyvinyl Chloride):

Polycarbonate: As previously mentioned, polycarbonate boasts high impact resistance, making it a favored option for applications requiring strength and durability. It also offers better heat resistance compared to PVC.

PVC: PVC is extensively used for pipes, fittings, and other construction purposes. While it falls short in impact resistance when compared to polycarbonate, PVC is valued for its chemical resistance and cost-effectiveness.

Polycarbonate vs. PET (Polyethylene Terephthalate):

Polycarbonate: Polycarbonate excels in impact resistance, withstanding strong impacts without shattering. It is also commonly used in applications requiring transparency, such as windows and protective barriers.

PET: PET is frequently employed for beverage bottles and food containers due to its exceptional clarity and recyclability. However, it lacks the same impact resistance as polycarbonate.

In conclusion, whether polycarbonate surpasses other plastic types depends on the specific requirements of the application. If impact resistance, durability, and transparency are paramount, polycarbonate is an excellent choice. However, for applications where cost or specific chemical properties are crucial, other types of plastics may be more suitable. It's essential to assess the specific needs and characteristics of each plastic type to determine the most fitting option for a particular project.

Rated Excellent

Rated Excellent